The Jibu Bottle Story

When we started Jibu in 2012, we assumed the business would follow the same path as every other drinking water social enterprise in the world: customers Bring Your Own Bottle (BYOB). Early on we stumbled upon a crazy theory that perhaps producing our own branded bottles might be a ‘secret sauce’ to transform the way underserved communities view water. The big ideas behind this were: 1.) why put good water in a bad bottle? 2.) piggyback on the extensive marketing of the big water companies to make it aspirational — finally everyone could afford what the rich drink and 3.) make a large bottle more functional than anything on the market, with a tap and a handle.

Back to the Beginning

Back to the Beginning

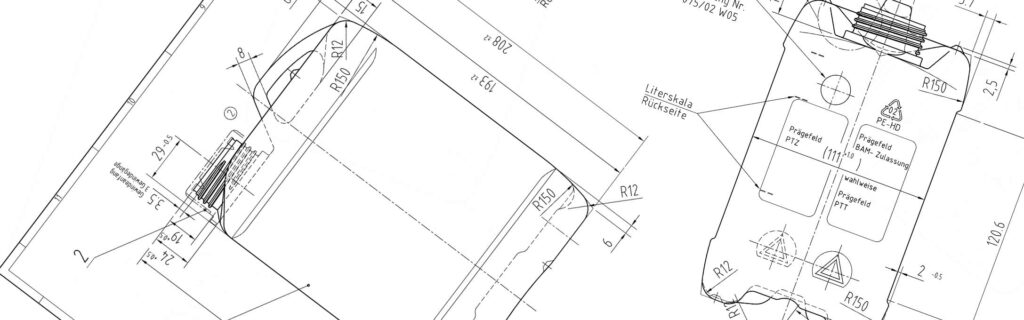

While performing our initial survey, we asked residents what they would pay for water. Our results found that people didn’t initially see the value of clean affordable water but when they saw the water in a nice bottle, in a clean store, they would be happy to pay for it. When deciding what bottle we wanted to use for our water, we quickly realized the very limited options available for existing bottles. Jerry cans were had no tap, and were too large and heavy for the average person to easily carry. Water dispenser jugs had similar problems. We tested a variety of sizes, shapes and weights and decided that 20 liters and 7 liters with built in taps were the most practical for customers. The 7L size was determined by market testing with women – we found that 5L was easy for every woman, 10L was difficult for many, and 7L was the amount nearly all women could comfortably carry.

In order to get a bottle that had a unique, recognizable and functional design, our only option was to create our own. Our purpose was to create an attractive bottle that wasn’t too heavy to carry long distances, and with an attached tap that could sit on a table and be easily dispensed. Also, creating a unique bottle design meant that our bottles wouldn’t fit in automatic bottle fillers, like jerry cans do, so that would increase customer loyalty since only Jibu could refill the bottles.

The Bottle Journey

The Bottle Journey

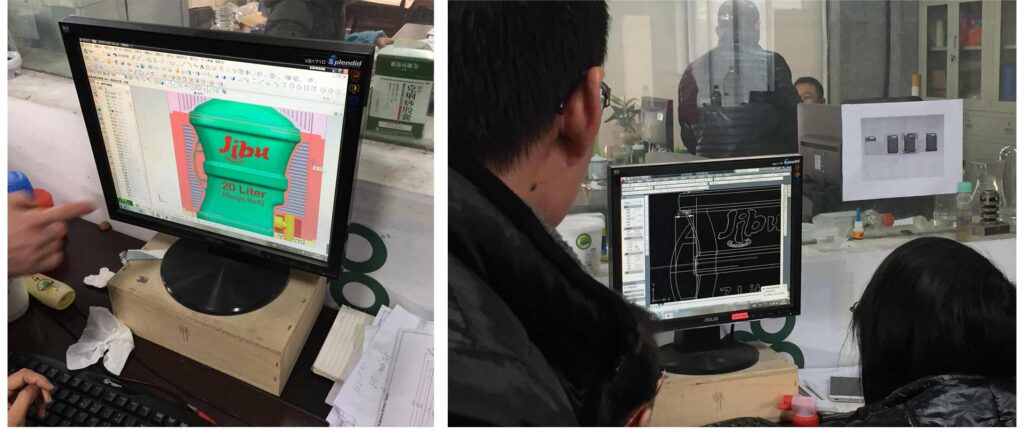

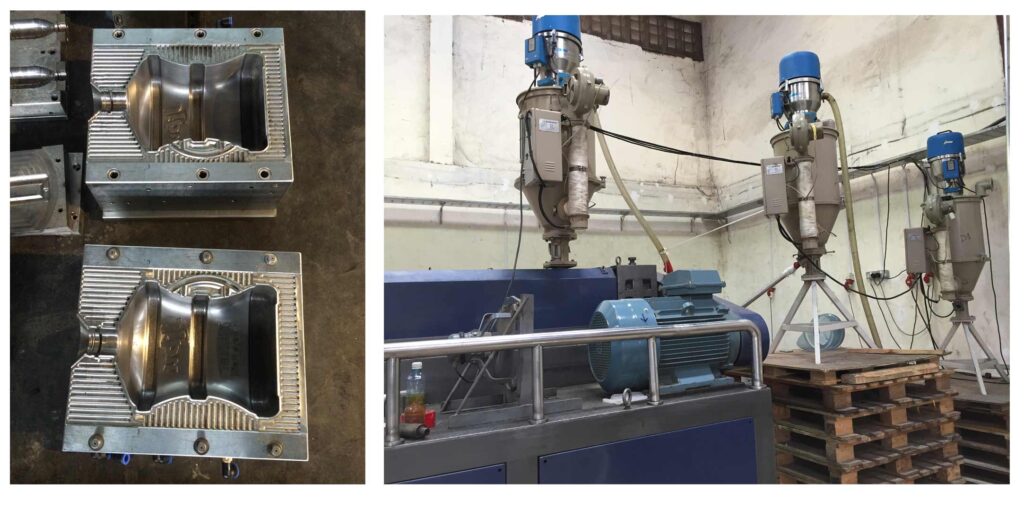

Our idea seemed easy enough: make a design, create a mold, start producing bottles. Anyone with experience in industrial design and production would understand otherwise. We wanted a bottle with durable heavy plastic so it would be long lasting, and most plastic manufacturers weren’t equipped to handle the type of heavy plastic we needed, so that limited our options. So we found a manufacturer in China who could make that mold, then ship the mold to Nairobi, Kenya, to a vendor who would produce the bottles.

We kept going back and forth with the Chinese mold maker. The models and samples they were creating kept coming out wrong. We ended up having to visit them personally in China to try and work through the problem. Turns out they weren’t using our original CAD models, but recreating them on their own, and losing many of the key features of the design. After some artful translation, and some creative negotiations, we got the mold complete, and made it’s way to Nairobi.

With a few modifications in Nairobi, the bottles finally became real! Next came the task of implementing them into our stores. Many franchisees were skeptical about the price, and whether customers were interested in a bottle that different from the other bottles on the market. As it turns out, our leap of faith worked! Customers loved the new bottles and it actually led to a huge increase in sales. The convenience of the tap was very popular and the durability of the bottles continues to be a game changer in the water business.